If you’re relatively new to electronics and wish to troubleshoot electronic devices on your own, it’s essential to have a proper knowledge of multimeters.

In the earlier days, we were limited to analog devices, which were quite difficult to operate. But now, you can find a variety of digital multimeters that allow you to select a wide range of measurements (manually or automatically). Also, it can display the measured values digitally on a screen, making it easy for even beginners to operate the instrument.

All digital multimeters can measure AC/DC voltages, currents, and resistance. Moreover, some even let you test continuity, hFE, capacitance, temperature, square wave, and frequency! In this article, I will guide you through everything that you should know about a digital multimeter and how to measure the different values.

Safety Tips Before Using a Digital Multimeter

If you’ve already purchased a digital multimeter, I highly recommend checking the user manual before operating it. It’s essential to know the basics and the warnings.

First and foremost, note the instrument’s category. The IEC (International Electrotechnical Commission) has defined four categories based on the type of load you’re going to measure. You can find these details in your operating manual or the instrument itself.

| Category | Application |

| CAT I | Electrical devices with high-voltage but low-energy |

| CAT II | Household appliances or portable tools that are directly connected to the electrical distribution system |

| CAT III | Hardwired equipment, polyphase motors, large building lighting systems, and circuit breakers (at the distribution level) |

| CAT IV | Primary electrical supplies and meters with low-voltage and high-energy |

Along with the category, I also suggest checking the electrical, environmental, mechanical, and safety instructions.

Dos and Don’ts of Using Multimeter

- Avoid water, liquid, and foreign bodies from entering the case and probes.

- Avoid using the instrument in case the battery is low, test leads are damaged, the battery cover is open, or you see any kind of malfunctions.

- Keep the multimeter away from flammable gases and explosive atmospheres.

- Never consider operating it on electronic devices that exceed the specified maximum voltages and currents.

- It’s a good idea to use protective equipment like gloves and safety goggles when operating the instrument.

- Ensure wearing electrically nonconductive clothes when performing any sort of tests.

- When establishing connections, always consider connecting the black (ground lead) first. Also, make sure you disconnect this one at the last.

- If you’re a beginner, it’s a good idea to first learn testing on electronically dead components.

- Always remove the test leads and turn the meter off when you’re going to open the multimeter’s chassis.

- Never consider replacing the parts unless you’re a professional or you’re supported by one.

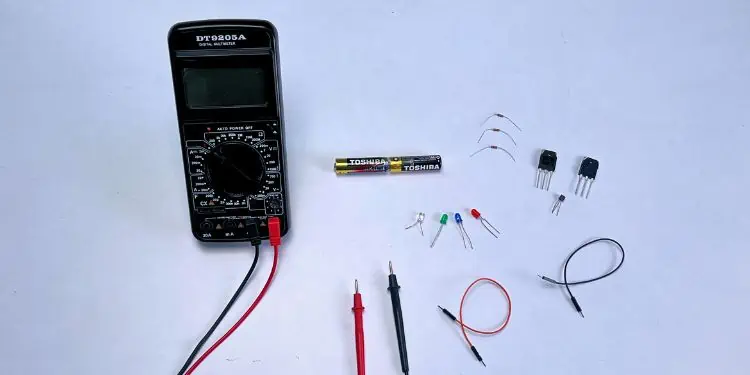

Different Parts of a Digital Multimeter

Now that you know the safety measures and precautions, it’s time to learn the basics. Without understanding all the parts of the digital multimeter and its functions, you won’t be able to operate it properly.

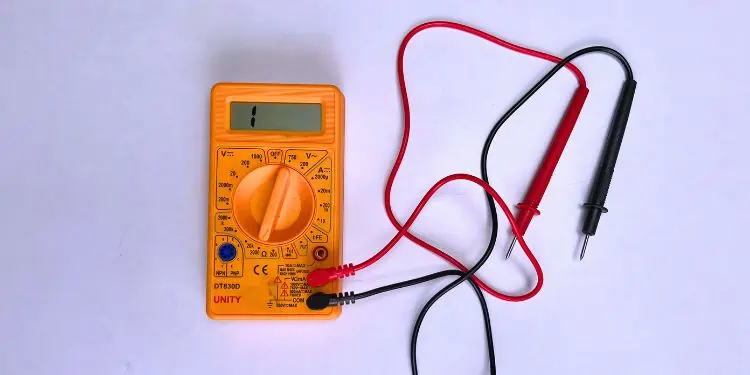

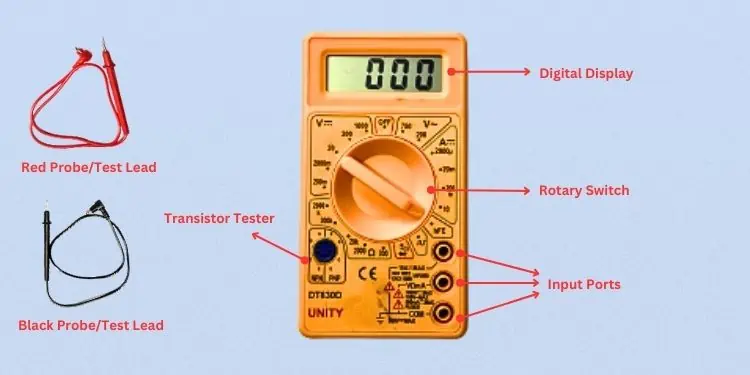

Looking at the above picture, you should already have a general idea about the instrument. Well, most digital multimeters have a digital display, rotary switch, and input jacks. However, some high-end products also come with extra buttons for additional functionalities. Let’s explore each of the parts in detail.

Digital Display

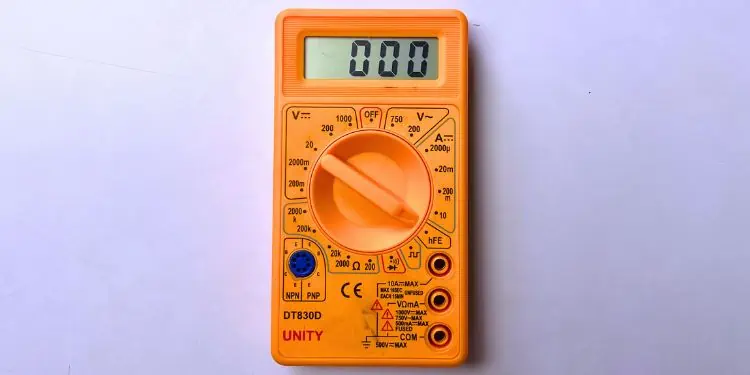

This is the most basic component of the instrument. Most multimeters incorporate illuminated LCD screens—some even have backlit for better viewing.

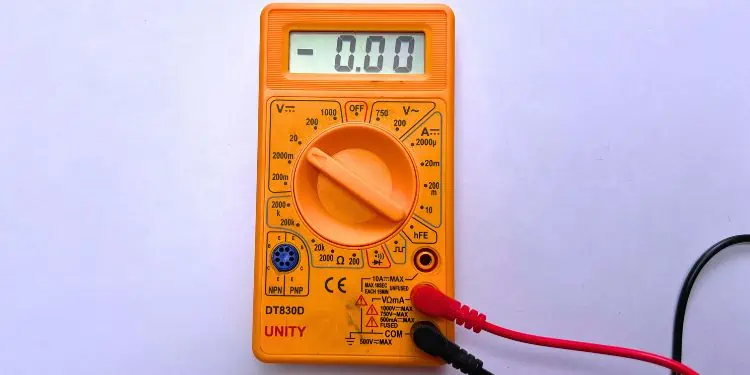

Unlike the traditional analog meters, they display in numbers which makes it easy for the users to read the measured values. It can display four values/digits and even a negative sign when the polarity is reversed (wrong positioning of the red and black leads).

Rotary Switch

It is simply the selector or dial positioned at the center that allows you to select from the range of AC/DC voltages, currents, and resistance. All you have to do is rotate the switch in different directions.

If you’ve got a device as pictured above (a manual-ranging multimeter), you require setting the measurement values manually. However, if you have an auto-ranging meter, you do not need to hassle with the ranges as they can automatically configure them.

During the measurements, it’s essential to know the appropriate symbols. AC voltage and current have a ‘∿’ notation that differentiates from the DC voltage and current, which is ‘⎓.’

Also, note that some cheap meters do not offer the measurement of AC current, like the one above in the picture.

Test Leads/Probes

Every digital multimeter comes with two test leads (Red and Black), also known as probes. These are simply the wires that let you connect an electrical circuit to the meter.

One end of the wire is a pointed probe that is meant to touch the source device. While the pointed probe is the most popular, there are other variations—including crocodile clips, hook clips, or even tweezer probes!

The other end of the wire is usually a banana jack, which needs to be plugged into the digital multimeter’s input ports, which I shall discuss ahead.

Some older models used to offer BNC connectors, but these days, most manufacturers use the shrouded banana jacks in the meters as per the IEC’s safety guidelines.

Input Ports

All the digital multimeters have at least three input ports—positive, negative, and a high-ampere (usually for measuring current range from 200mA to 10A). However, newer instruments also have a fourth port for the temperature, volt, resistance, and diode test.

The negative or also called the common input port is usually labeled COM. This is where the black probe is connected and is connected to the ground of an electric circuit. No matter what you’re trying to measure, this must always be plugged in.

On the other hand, the positive or also known as the current port, is where you plug in the red probe. This is used for measuring current up to 200 mA and is mostly represented with the label mAVΩ, VΩmA, or V/Ω/Hz.

Likewise, the third port (labeled just A, 10A⎓MAX, or 20A) is used when you’re trying to measure larger currents (greater than 200mA). Here, you require connecting the red probe.

Note: Always check the maximum supported voltage, current, resistance, and also the time limitation (when measuring high amperes) next to the input ports before operating your digital multimeter.

Transistor Tester

Most digital multimeters have a transistor tester embedded into them. There are two separate fields for testing both types of transistors (NPN or PNP). When doing so, you need to configure the Emitter-Base-Collector appropriately, ensuring they are at the correct terminals.

Moreover, when testing transistors, it’s essential to point the rotary switch to the hFE field. In case you’re not getting the reading, you might want to reverse their position to get accurate results.

Input Buttons

If you have a newer DMM model, it’s likely equipped with multiple buttons. In some models, you get a Range button to manually set the range or simply set it to Auto.

Likewise, there are other buttons with dedicated functions, like Data Hold, Min/Max Mode, Back Light, On/Off, Frequency Counter, Relative Measurement, Shift, and many more.

Since the number of buttons differs based on the DMM type, I am not going to get detailed into them. Instead, you can look up the operator manual to know how they work and when you should use them.

How Does a Digital Multimeter Work?

While there can be a broad range of digital multimeters, the working principle remains the same. Once you get to know how the device works, it’s not at all tedious to use it.

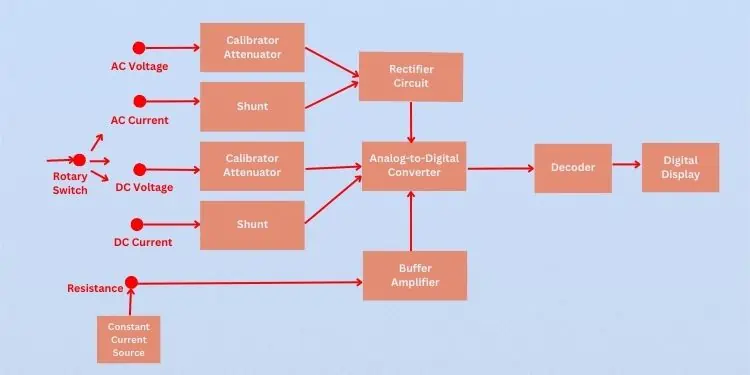

As per the block diagram above, to find the AC voltage of the circuit, it is required to first set the rotary switch to an appropriate range. Next, the calibrated attenuator converts the higher volts to lower volts. Then, the rectifier circuit (also known as the precision AC/DC converter) converts the AC voltage into DC voltage. Finally, the generated analog values are transformed to digital by the Analog-to-Digital Converter which is then displayed on the LCD screen.

Similarly, if you’re trying to measure a DC voltage, it is necessary to set the rotary switch first. Then, the higher volts are calibrated into lower volts as discussed earlier. Since this is a DC voltage, it doesn’t require a connection to the rectifier circuit and the AC/DC converter converts the DC analog signal to digital, which is now displayed on the screen.

While measuring the voltages required a calibrated attenuator, the measurement of currents requires shunts, which basically coverts the high current to lower. Now, if you’re trying to measure an AC current, it first passes through the rectifier circuit (to convert AC to DC) before the conversion to a digital signal. On the other hand, when measuring DC current, this is directly done. Once the final conversion is completed, the final value is shown on the digital screen.

To find the resistance, we should first point the rotary switch to the appropriate resistance range. Unlike the other measurements, we require a constant current source here that provides the necessary amount of amps.

Now, the digital multimeter finds the voltage drop in the circuit, and with the help of Ohm’s law (Resistance = Voltage / Current), resistance is calculated. Finally, the buffer amplifier will provide the electrical impedance transformation (i.e., provide the best loading condition), and the analog signals get converted to digital before the final output on the screen.

How to Use a Digital Multimeter?

As mentioned earlier, a digital multimeter helps you measure voltage, current, and resistance. Additionally, it allows you to test continuity, a transistor’s hFE, frequency, and more. Regarding the same, I will discuss the step-by-step guide on measuring each of them.

Measuring Voltage

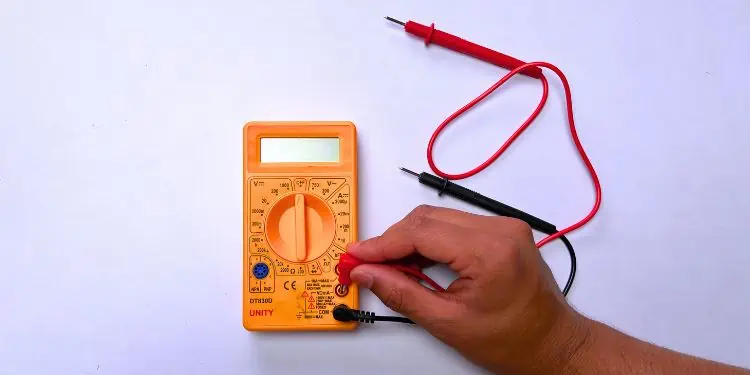

- First of all, plug the black probe/test lead into the COM port of the DMM.

- Next, plug the red probe into the mAVΩ, VΩmA, or V/Ω/Hz (current) port.

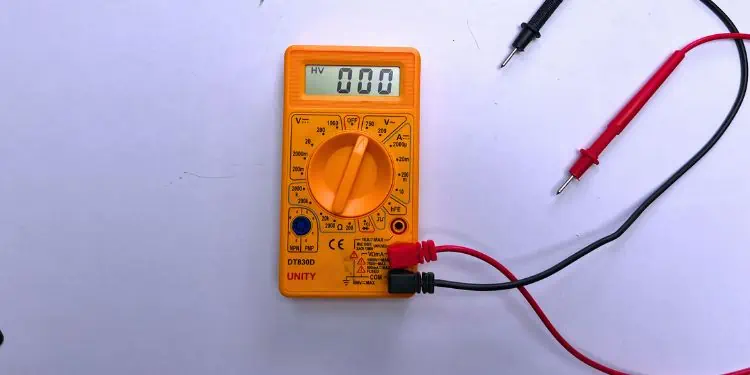

- Then, turn on the multimeter (if yours has a dedicated button for it).

- Now, rotate the dial/rotary switch toward the AC/DC voltage field depending on the type of voltage the device stores. Then, use the probes to compute the AC/DC voltage.

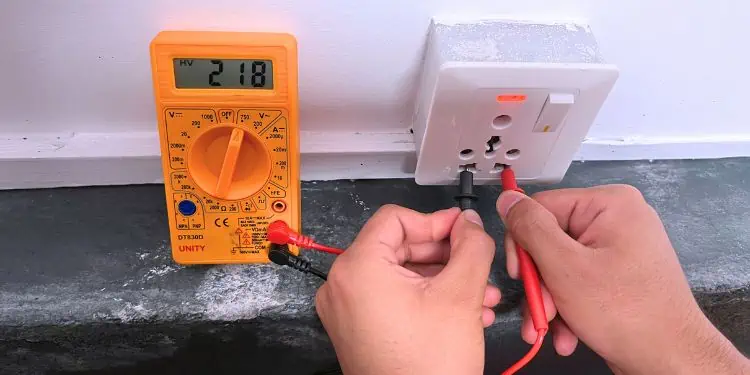

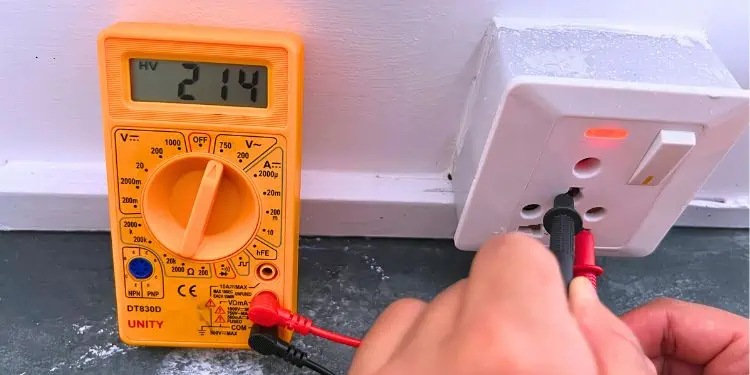

For example, to check the AC supply voltage on your house, here’s what you can do:

- First, search for the supply voltage of your country. Usually, this is around 120-250V.

- Set the dial to AC Voltage (V with the ~ symbol) and the value should be greater than the supply voltage. Let’s say, the supply voltage is 230V. This means that you’ll have to set it to at least 250 or higher. In our device, the higher value than 230V is 750V. So, I set the dial to 750V. Note that if you set the dial to a lower voltage, you might brick the device!

- Now, hold the test leads at the bottom ensuring you do not touch the tip of the leads and the two tips do not touch one another. As always, take extra care when getting near the wall socket as well.

- Next, plug one of the wires into the left and another into the right. You can even revert them to test for yourself.

- Then, you can even try testing the voltage of the ground hole. Plug the black probe into the single hole on the top/bottom. Then, plug the red into any of the left/right holes and note the reading. If you get no reading or low value than the standard supply voltage, note that your house is not properly earthed.

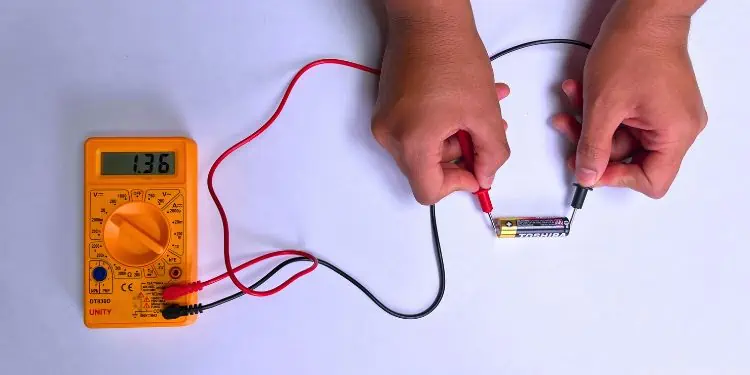

While this was for measuring the AC voltage, here’s a simple example of how to check the DC voltage of a 1.5V AA DC battery:

- First, you need to move the dial to the DC Voltage (DC) and set the value to 2V or higher. In ours, I am going to set it to 20V.

- Next, touch the black probe’s tip to the negative side of the battery.

- Then, touch the red probe’s tip to the positive side of the battery.

- Now, note the voltage reading from the digital screen. If you’re getting the actual amount of voltage, this means it’s fully charged.

- If you’re getting a negative value, it means that you’ve touched the tips to the wrong sides of the battery. You do not have to worry as this is not going to destroy your meter. Instead, it’s just providing you with the reading for the negative terminal of the circuit.

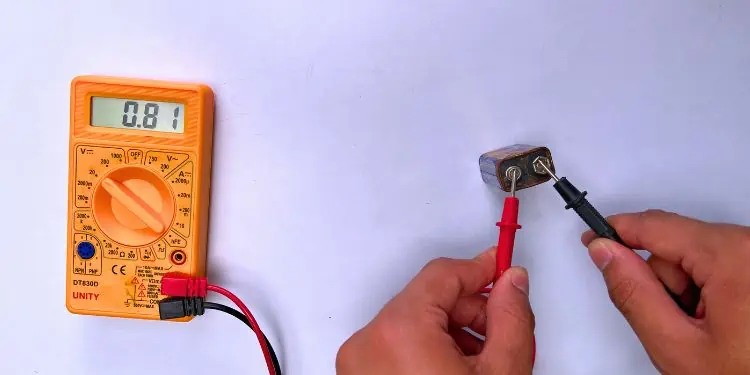

- However, if you’re performing this on an electronically dead battery, you’ll likely get a reading of less than 1. Here’s what we got when I tested on a 9V DC battery:

- Once you’ve noted the voltage readings, you can set the dial to Off.

- Finally, disconnect the red probe first followed by the black one.

Measuring Resistance

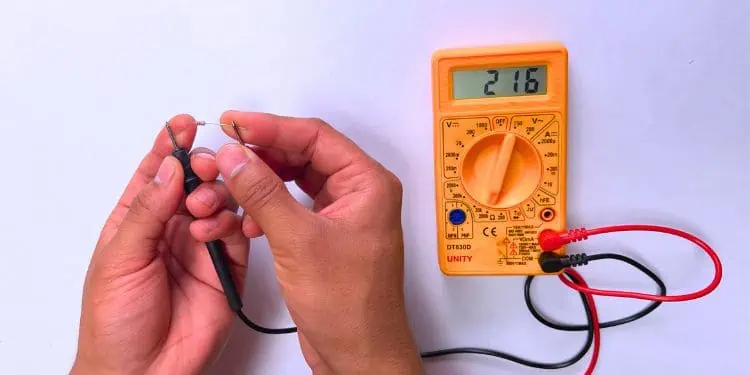

For testing purposes, I am going to check the resistance of a 220Ω resistor. If you’re unaware about its value, you can compare the color code with the online chart.

- Start by plugging the black probe into the COM port and the red one into the VΩmA port.

- Now, rotate the dial to the Ω field and set it to the appropriate value (always set it to the one higher than the resistance). As you can see, for the 220Ω resistor, I have set it to 2000.

- Next, press and hold the black probe against one end of the resistor.

- Then, touch the red probe to the other end.

- Note the resistance from the digital screen.

- Finally, unplug the black probe followed by the red one.

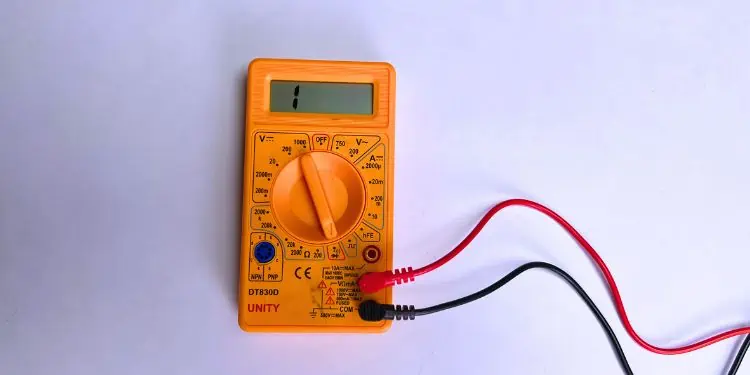

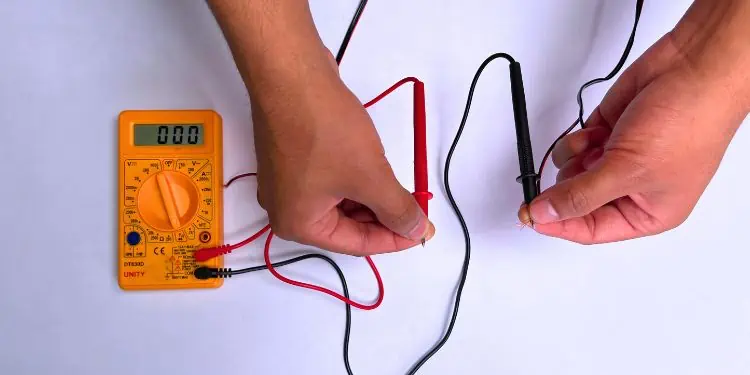

Testing Continuity

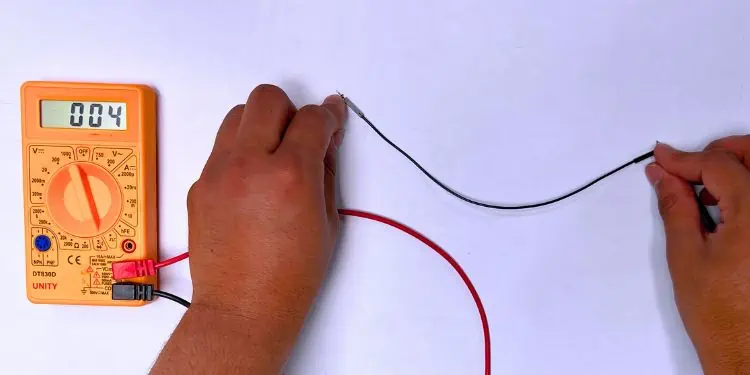

In this section, I will test the continuity on a piece of wire—jumper cable. You may use any other equipment to ensure it is not damaged and is in proper working condition.

- First of all, connect the black and red probes to their respective ports, as discussed above.

- Next, set the dial to the continuity field (one with a diode symbol and a sound wave symbol).

- Now, touch the black test lead to one end of the wire and a red one to the another. The DMM should produce a ‘beep’ sound and the value should change from ‘1’ if there’s continuity.

- Using a similar technique, here’s how to test the continuity of a jumper cable. If you’re getting a 0 or minimum value, it means there is perfect continuity. However, if you get a higher reading or simply 1 or OL, it means the circuit is open, and there’s no continuity—meaning the current is not flowing).

- Once you’re done, set the dial to Off, and unplug both probes.

Measuring Current

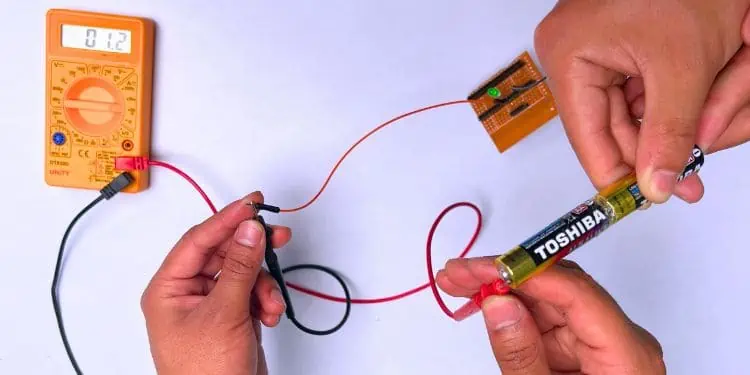

For testing purposes, I first created a simple circuit comprising a 2.68V DC battery, a green LED (voltage requirement of 1.9-4V) and a jumper cable. and a matrix board to measure Direct Current (DC).

Since this is just a beginner’s guide to using a multimeter, I have not included the necessary steps for measuring Alternating Current (AC). It can be a risky process and can prove to be fatal. If you’re already an expert, you can use a similar procedure with extreme precautions or use a clamp meter.

- Plug the black probe into the COM port.

- Then, plug the red probe into the 10A port. However, if you’re aware that the created circuit is less than 200mA, you may use the VΩmA port too.

- Next, switch the dial to the DC Current field.

- Break the circuit by simply disconnecting the positive terminal of the circuit.

- Then, connect the DMM in series to the circuit. This means I touch the red probe to the positive side of the battery and the black probe to the negative side of the LED.

- Now, the LED should glow and you should see the reading on the digital display.

- Once the measurement is complete, you can now disconnect everything and also set the dial to Off.

hFE Test for Transistors

Hybrid parameter Forward current gain, common Emitter (hFE) determines a transistor’s current gain or amplification factor. Every transistor has its own hFE value, and it ranges from 10 to 500. To test yours, follow this quick steps:

- Set the dial to the hFE field.

- Based on the transistor type (NPN or PNP), insert the collector(C), base(B), and emitter(E) into the appropriate holes of the respective field.

- In case there’s no reading, try readjusting the transistor until you see the hFE value on the digital screen.

- Once you’ve noted the values, you may not set the rotary switch to Off and disconnect the probes.

Computing Square Wave Output, Frequency, and Temperature

Along with voltage, current, resistance, continuity, and hFE, it’s also possible to compute the square wave output using any digital multimeter. To test this, you may use an oscilloscope or build one using Arduino. Then, use its software to measure the frequency.

Unlike the low-end DMMs, some high-end instruments let you measure the frequency directly as they have a separate Hz field.

Likewise, some also allow measuring temperature. You can check your manual to learn more about them.