Thermal paste mainly comes in two variants — standard thermal pastes that use a base matrix (like silicon-based) and liquid-metal-based ones.

PC enthusiasts praise liquid metal as the best Thermal Interface Material (TIM) for cooling. Some users have even claimed that it drops the temperature by whooping 10°C or more.

However, it is quite risky to apply liquid metal paste without proper precautions and experience. So, depending on your situation, it may be better to use other regular thermal pastes instead.

What is Thermal Paste?

Standard thermal pastes use a base matrix together with a thermally conductive filler to provide a fluid pasty consistency. Most common thermal compounds are silicon-based.

But you’ll also find carbon-based, ceramic-based, diamond-carbon-based, and metal-based compounds on the market.

The matrix usually contains silicones, acrylates, urethanes, and epoxies, which are thermal insulators. The paste has to rely on the fillers that make up 70-80% of its composition to provide thermal conductivity.

These fillers are either one or a couple of — aluminum oxide, zinc oxide, boron nitride, aluminum nitride, and carbon micro-particles. Depending on the type of the thermal paste, it may contain additional substances like silver and aluminum dust (metal-based), diamond powder (diamond carbon-based), and so on.

What is Liquid Metal?

Unlike the regular thermal pastes I’ve discussed above, liquid metal directly uses metal that stays liquid at room temperature instead of relying on a base matrix.

The metal is usually an alloy of gallium, indium, and tin, where the gallium is the main component.

Since all the thermal interface material is a metal, it has much higher thermal conductivity than other types of thermal paste and allows better dissipation of heat to the cooler.

This thermal interface material is especially preferred by PC enthusiasts who want to overclock their CPU and want the lowest possible temperature for their CPU.

Differences Between Thermal Paste and Liquid Metal

While standard thermal pastes and liquid metals have the same working mechanism, their composition brings about certain differences that make them stand apart from one another.

Heat Transfer/Dissipation and Cooling

While figuring out how good of a cooling solution liquid metal or other thermal pastes make, we need to consider their thermal conductivity. The higher the thermal conductivity, the better it can dissipate heat and maintain an effective cooling system.

Both types of thermal interface material can’t hold a candle to that of the heat sink (Aluminum – 237 W/m.K, Copper – 400 W/m.K) in this regard. However, it’s better to use an interface material with as high a dissipation rate as possible.

The thermal conductivity of regular thermal paste’s base matrix is about 0.17-0.3 W/m.K. Depending on the filler material, the total thermal conductivity of the silicon or carbon-based paste usually gets raised to 0.5 – 4 W/m.K.

Some high-end thermal pastes like silver-based or diamond carbon-based ones can have thermal conductivity ranging from 3-8 W/m.K. According to ARCTIC, any values higher than this are likely mere embellishments.

For liquid metals, the thermal conductivity can go beyond 13 W/m.K. The main substance in most liquid metals is Gallium, which has a thermal conductivity of 33.68 W/m.K.

However, it is generally used as an alloy with Indium and Tin, and the liquid metal’s paste generally ranges from 17-40 W/m.K.

Many high-end liquid metal TIM manufacturers also sell products claiming a thermal conductivity of 70-80 W/m.K.

Drying

Standard thermal pastes use solvents to hold all the filler with a pasty consistency. With regular exposure to high heat, these solvents gradually evaporate, causing the paste to dry out.

Liquid metals don’t need to use such solvents, so they don’t dry out or show any degradation over time.

Corrosion

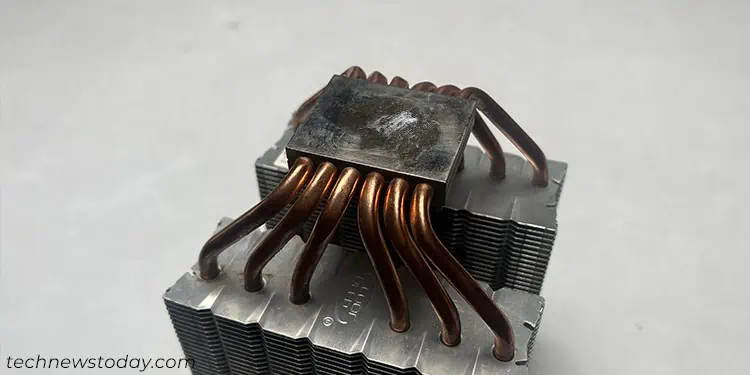

While the liquid metal does not dry out over time, its main material, Gallium, is very reactive and can corrode other materials. You will especially see this issue with Aluminum base or heat sinks on the cooler.

So, you should only use liquid metal with compatible coolers that have copper or nickel-plated base.

Even with copper/nickel, it can create an alloy that leads to discolorations in the base plate. It happens over time, especially due to the constant exposure to heat. But it won’t affect the heat exchange process much, so you can rest assured.

Regardless, I personally recommend using coolers with nickel-plated bases if you want to use liquid metal, as it is the slowest at forming the alloy.

As far as other thermal pastes are concerned, they don’t contain any such corrosive elements.

Electrical Conductivity

Apart from corrosion, you also need to worry about the electrical conductivity of the thermal interface material.

Most thermal pastes (silicon, carbon, diamond carbon, or ceramic-based) are not electrically conductive. So using them won’t cause any short circuit issues if they leak into electronic circuit elements.

Thermal pastes that have metal fillers can be electrically conductive, and you need to be careful not to spill it into any circuit parts. It’s also better to use electrical tape on nearby components to account for unexpected leaks.

As for liquid metals, think of them as metal-based thermal paste but worse. They are much more electrically conductive and can cause severe damage due to short circuits if they ever leak to other PC components.

Cost

The high thermal efficiency of liquid metals directly corresponds to their price. Depending on the quality of the liquid metal TIM, it can cost anywhere between $10 and $20 per gram.

For other types of thermal paste, you can usually buy them at about $1 – $4 per gram. Diamond-carbon-based thermal pastes will cost slightly more but not as much as liquid metal.

On the flip side, you need to use a low amount of liquid metal every time, and you don’t have to replace it as much as regular thermal paste, so it won’t be as expensive in the long run.

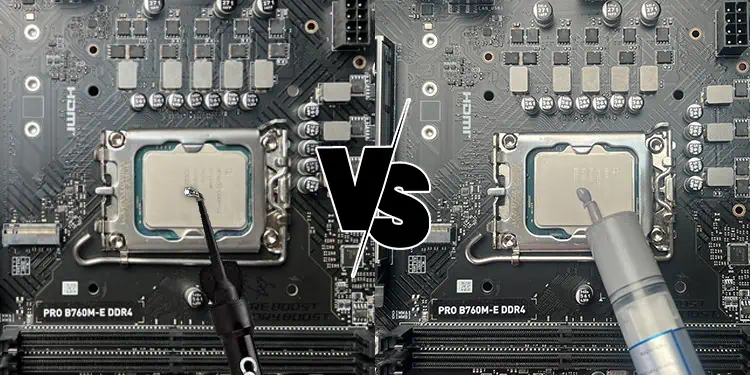

Ease of Application

Since liquid metal can harm the PC components, you need to be very careful while applying it. You need to apply a very thin layer of the liquid metal evenly using a spreader while avoiding spills or leaks.

Just using a pattern or depositing it in the middle as with standard thermal pastes, is not recommended for this TIM.

Also, while neither regular thermal paste nor liquid metal are toxic, they can cause slight harm to the human body. In this regard, liquid metal is more harmful, and you need to be even more careful while handling it so that it doesn’t get to your eyes or you don’t inhale any fumes.

It’s better to be in a well-ventilated room and use gloves and a protective eye mask.

Which Thermal Interface Material Should I Use?

If you have prior experience in using liquid metal or can get help from such a person, and you are going to push your CPU to its limits, you can install it as long as you don’t use any coolers with aluminum base.

Otherwise, standard thermal pastes should be more than enough for your use. Unless you are overclocking your PC or have a very heavy workload, the CPU temperature difference would not be that high compared to liquid metals.

If you are looking for a high-end solution, diamond carbon-based ones should provide very good thermal dissipation without introducing any risks that come with liquid metals.

If you really want to use liquid metal, make sure to use electric tapes on all nearby components and around the CPU to prevent damage due to leaks. Also, keep in mind that applying liquid metal leaves a conspicuous mark on the heatsink, so you run the risk of voiding your warranty.