Your PC contains many components that heat up, like CPU, GPU, SSDs, etc., which require proper heat sinks/coolers. So, it is important to use a thermal interface material (TIM) between the components and the heat sinks for better dissipation of heat.

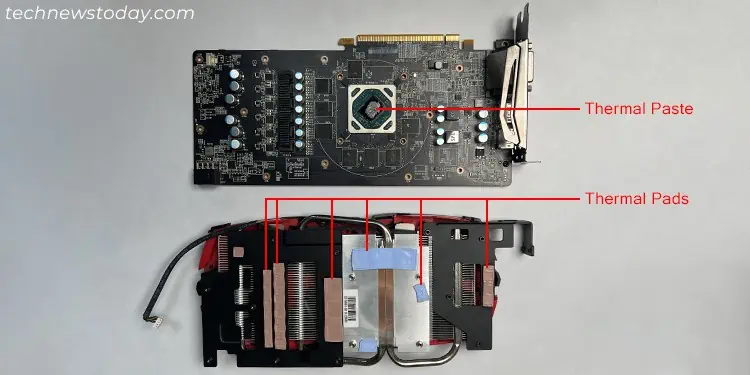

If you are new to building a PC, you might want to know which TIM is the best choice for each device. The short answer is that you need to use thermal paste or thermal grease with processors (CPU and GPU). For other components like Voltage Regulator Modules (VRMs), Video RAMs (VRAMs), and NVMe SSDs, it’s best to use thermal pads instead.

Before I get to why it is so, you need to understand the basics of thermal paste/grease and thermal pad, along with their differences. Thermal paste and thermal grease are basically the same, so I will be comparing them to thermal pads in this article.

What is Thermal Paste or Thermal Grease?

Thermal paste or thermal grease is a viscous mixture containing a non-curing polymer base matrix and thermally conductive filler particles. The filler is usually composed of Aluminum oxide, zinc oxide, boron nitride, or aluminum nitride. But depending on the type of thermal paste, it can also contain diamond powder, silver powder, microcarbon particles, and so on.

The polymer base is usually made of silicones, epoxies, urethanes, or acrylates and is not thermally conductive. It simply gives the pasty fluid consistency to the thermal interface material, and the paste actually relies on these fillers for heat dissipation.

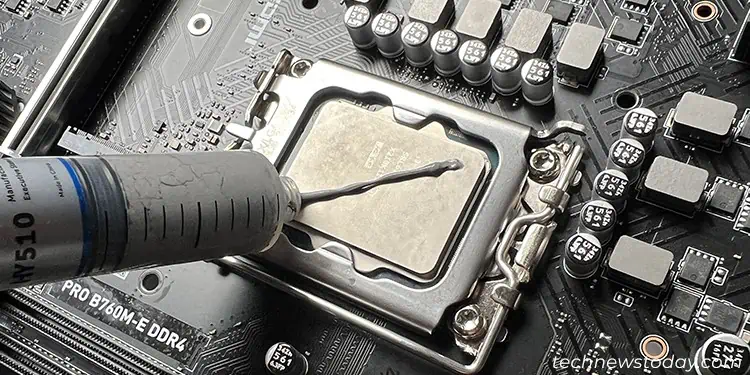

You will usually find the thermal paste or grease in a syringe or a plastic jar-like container. Previously, the thermal interface paste available in plastic jars were called thermal grease, and those in syringes were called thermal paste even though they held similar substance. Now, the terms are used interchangeably.

What is a Thermal Pad?

A thermal pad is a preformed solid rectangular thermal interface material. Depending on the softness of the pad, it has a spongy or clay-like consistency. It is made by curing a silicone or paraffin wax polymer filled with thermally conductive filler.

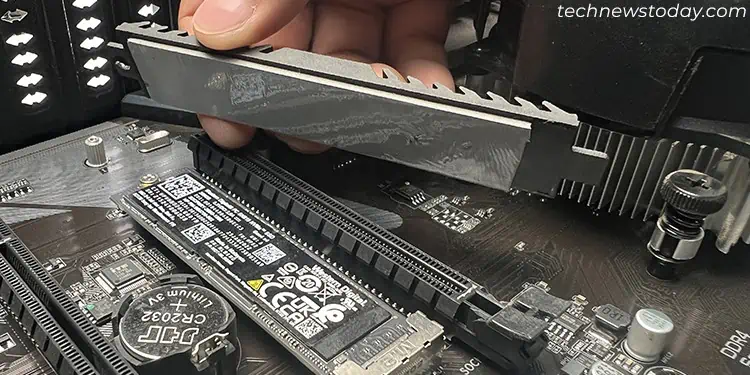

It is available as rolls or sheets of a specific thickness (usually 0.5mm, 1mm, or 1.5mm), and you can cut the required dimensions per your need. Many heat sinks like those for NVMe SSDs also come pre-applied with thermal pads.

This pad remains solid when at room temperature but softens up at a higher temperature, filling the air gaps between the heat sink and the computer device.

Differences between Thermal Paste Vs Thermal Pad

Both the thermal pad and thermal paste serve to maintain proper contact between the computer device and the heat sink. However, the difference in their consistency and make-up give rise to certain differences.

Purpose

The purpose of thermal paste or grease is to fill in all the microscopic gaps between the PC component and the heat sink. On CPU and GPU, the cooler’s heat sink directly contacts the processor even without the paste. But due to surface imperfections, a lot of air gaps remain in between.

These gaps don’t allow proper heat dissipation and can cause overheating issues. Hence, you need to fill them with materials that provide more thermal conductivity— thermal paste.

Thermal pads, however, are generally supposed to fill in the larger gap between the device and the heatsink. For NVMe SSDs or VRAM/VRMs of the graphics card, their heatsink normally does not touch these components. So you need to use thermal pads with proper thickness to maintain contact between them.

It is possible to use thermal pads for components where you need thermal paste, like the processors. But it won’t be as effective as it can’t fill all the microscopic air gaps.

Thermal Conductivity

Both thermal pads and pastes use a thermally conductive filler along with a base material that gives it their consistency. However, since the nature of the base material and their portion varies, pads and pastes have different thermal conductivity.

In general, thermal pastes are better heat conductors and provide higher cooling performance. High-quality thermal pads that provide a comparable efficiency to standard pastes are also available in the market. But you can find high-quality pastes that surpass any kind of thermal pads.

Electrical Conductivity

Generally, regular thermal pastes and thermal pads are not electrically conductive. But metal or liquid metal-based thermal pastes use metal elements to improve heat conduction, so they are also electrically conductive. Leaking these pastes to the electronic components can damage these components due to short circuits.

Ease of Application

Installing a thermal pad is much easier compared to thermal paste. First, you need to get or cut the pad with the dimensions you need. Then, you have to peel out the protective film on one side, apply the pad to the device or heat sink, and peel out the protective film on the other side.

Finally, you can attach the heatsink to the device after applying all the necessary thermal pads. You just need to be careful not to touch the pad with your fingers or expose it to dust after removing the film.

As for thermal paste, you need to eyeball a suitable amount of the paste and apply it in a proper pattern. The goal is to have the paste spread over the surface of the processor after installing the cooler.

The paste can also get to your fingers, clothes, furniture, or even the PC components like CPU sockets. So you need to be very careful while applying it.

Reusability

After using thermal paste once, you will need to clean it off and reapply it if you ever need to reinstall or replace the heatsink. The old paste will not be able to keep a consistent form and spread over all the necessary areas if you don’t replace it.

So you need to clean and replace it to be able to properly fill the microscopic gaps.

But it is possible to reuse the same thermal pads more than once as long as they remain clean. Since it is a soft but solid substance, it will usually act the same way after reinstalling the heat sink.

Thermal pads also usually last longer than thermal pastes as the paste dries out with time due to the gradual evaporation of their solvent. Thermal pads also suffer from degradation over time, but the rate is somewhat slower.

On the other hand, thermal pastes come in tubes, so you will be able to use them multiple times within its shelf life of 2-5 years. Thermal pads may have a higher shelf life, but since you won’t be buying a much bigger pad at once, you will likely use it up faster compared to thermal pastes.

Stability

Even though thermal pads are soft, they remain solid and stay in one place after you apply them. On the other hand, if you apply a thicker layer of thermal paste, it can move over time due to the constant cycle of heating and cooling.

It is not a problem if you use a proper amount of the paste. But it is something you need to be careful about if you are new to PC building, as you don’t want the paste to spill over and get to other areas like the CPU socket.

Which Thermal Interface Material Should I Choose?

While thermal pads cost slightly more per unit compared to thermal paste due to their more complex manufacturing process, the difference is negligible in the long run, considering its reusability. You actually need to consider other factors, especially the purpose, ease of application, and thermal conductivity.

For processors like GPU and CPU that can get very hot, you need to use a better thermal conductor. So, always go for thermal paste for these devices. Thermal pads do not provide anywhere near the cooling efficiency that you’ll get from thermal pastes, especially high-quality ones.

On NVMe SSDs and VRMs/VRAMs on graphics cards, you need to use a thermal pad. Even their manufacturers produce these devices with the thermal pad in mind and design them such that there will be some space between the device and the heat sink.

These components also don’t get nearly hot enough to need the higher thermal conductivity of thermal pastes.